THE VALUE

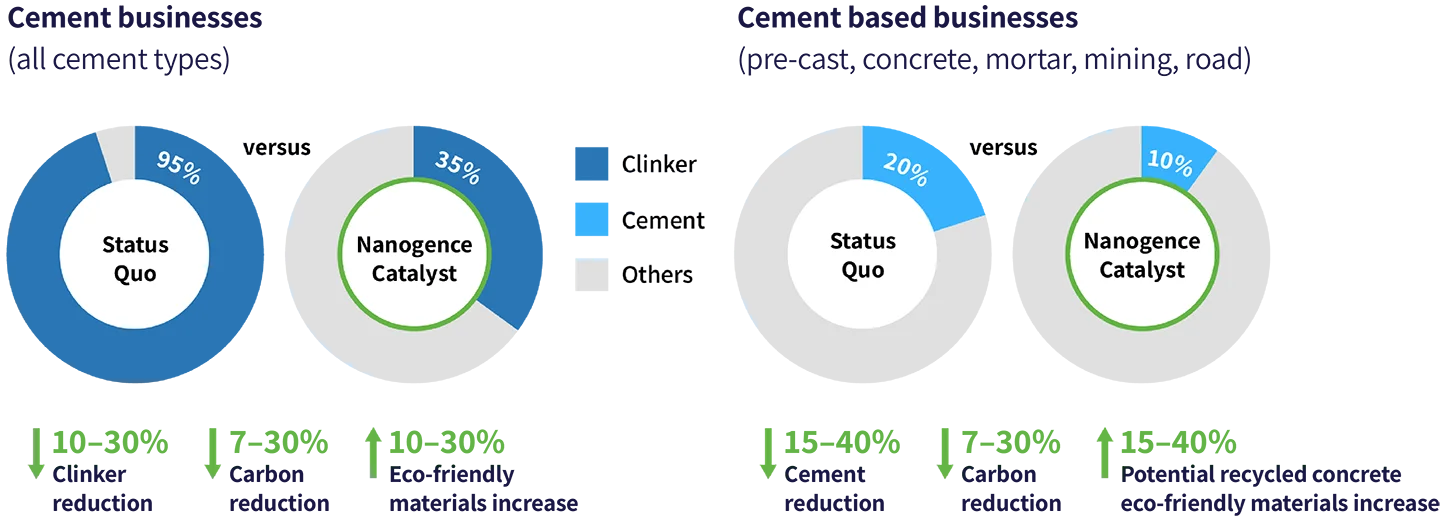

Reducing the cement content in a Nanogence-enhanced concrete mix provides opportunities for cost savings as well as a reduced carbon footprint. Our catalyst platform enables significant reductions, depending on mix design and regulatory norms. To put this into perspective, let’s consider common concrete production metrics:

![]()

Per Cubic Meter of Concrete

Standard concrete mixes typically use 300–400 kg/m³ of cementitious materials, including cement and supplementary cementitious materials (SCMs). A reduction of 25–100 kg/m³ represents a 7–33% decrease in cement usage, depending on the initial mix composition.

![]()

For Same Strength Performance

![]()

Beyond the cost savings, this reduction has a meaningful impact on the environment. For every kilogram of cement reduced, approximately 0.4–0.8 kilograms of CO2 emissions are avoided.

![]()

Long-Term Durability

Our breakthrough in material chemistry enhances matrix packing at the nano and micro levels, delivering exceptional long-term durability. This results in:

- Greater resistance to chloride penetration, carbonation, and shrinkage-related issues.

- Enhanced protection against alkali-silica reaction (ASR), efflorescence, and acid sulfate reduction.

- More durable, longer-lasting structures that require less maintenance over time.

![]()

Value-Added Benefits

Clients adopting Nanogence’s solutions gain access to these government incentives, improving their ROI while contributing to global sustainability goals.

- Carbon Credits: Our clients can benefit from carbon credit systems as they adopt Nanogence’s low-carbon solution.

- Green Building Certifications: The use of Nanogence technology can support projects in achieving LEED and other green building certifications.

- Tax Incentives: By adopting Nanogence’s catalyst platform, clients can access government-backed tax incentives aimed at supporting sustainable construction.

Carbon Reduction Impact

Nanogence’s catalyst platform plays a key role in reducing the carbon footprint of concrete used in large-scale projects. In a major airport project, we were able to reduce cement content by up to 30%, resulting in a direct reduction of embodied carbon.

This was accomplished through a combination of our catalyst technology and regionally sourced materials, which also minimized transportation emissions. The results were measurable: a 24% direct reduction in carbon emissions and 17% cost savings from optimized material efficiency and waste reduction.

By adopting Nanogence’s solutions, clients actively contribute to global carbon reduction goals, achieving both cost savings and environmental benefits while ensuring seamless integration into large-scale infrastructure projects.

![]()